Speed bumps and speed humps

Speed bumps and humps are essential traffic calming measures for private car park safety management, helping to slow vehicles in private areas. Our road humps meet UK and European standards while offering high performance at a competitive direct factory price.

-

Speed Bump 5 cm

$22.10 – $28.70 -

Speed Bump 7 cm

$31.50 – $44.50 -

One-Part Speed Bump

$5.50 – $35.70 -

Speed Hump 3 cm

$3.90 – $10.10 -

Speed Hump 5 cm

$5.70 – $21.70 -

Speed Hump 7 cm

$10.10 – $35.60

| Picture | Model | Speed Reduction | Benefits | Ideal For |

|---|---|---|---|---|

|

5 cm Speed Bump |

Approx. 9 mph (15 km/h) | Slows cars and light vans, clearly discouraging speeding | Retail car parks, warehouse staff car park gates, warehouse yards |

|

7 cm Speed Bump |

Approx. 6 mph (10 km/h) | Extra height slows heavy vehicles, for heavy-duty use | Busy loading bays, major distribution depots, airport cargo roads |

|

One-part Speed Bump |

Approx. 9 mph (15 km/h) | Single-piece design for quick install, ideal for small areas | Small private car parks, factory staff entrance, gated residential roads |

|

3 cm Speed Hump |

Approx. 21 mph (35 km/h) | Gentle speed reduction for smoother emergency and service vehicle access | Residential streets, university campus roads, hospital internal roads |

|

5 cm Speed Hump |

|

Balances safety and comfort, slows traffic on medium-speed roads | Retail park internal roads, industrial area |

|

7 cm Speed Hump |

|

High profile for strong speed reduction in high-traffic areas | Large commercial car parks, busy internal roads, airport service roads |

What are Road Speed Bumps and Humps?

Speed bumps and speed humps, also known as road humps or sleeping policemen, are traffic calming devices designed to reduce vehicle speeds. To ensure smoother passage, speed humps are designed with a wide and gentle shape.

Common materials include rubber, metal, plastic or concrete, depending on different application.

While speed cushions and speed tables are used on public roads, speed bumps are installed in private areas where stronger speed control is needed.

Permanent Yellow, No Paint, No Fade

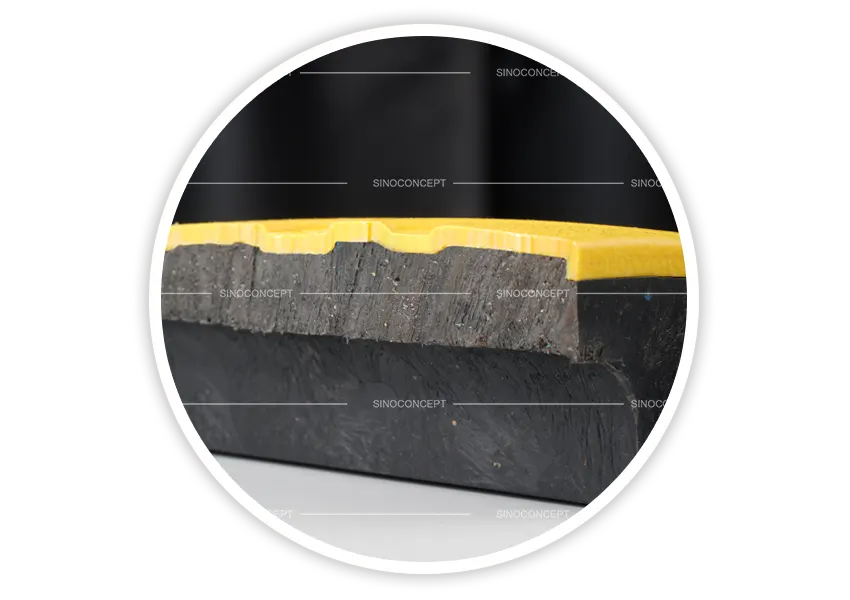

Sino Concept’s road ramps feature a thick yellow cover that is moulded directly into the black material.

We don’t apply paint to our road ramps, so there is no risk of fading, peeling, or the need for repainting.

Key Features of Our Plastic-Rubber Speed Bumps for Sale

Our speed bumps and humps are built for durability, ease of installation, and long-term use to reduce speed as road calming measures in various traffic conditions.

All speed ramps from Sino Concept are supplied as a complete speed bump kit with mounting hardware, making stock management easy.

Robust Materials

Made from REACH-compliant, tough plastic-rubber composite for easy export to Europe, our sleeping policemen resist wear and deformation under frequent use, even in poor weather conditions.

Skidproof Surface

Our road humps feature a textured anti-slip surface that provides excellent grip for both vehicles and pedestrians. This design reduces the risk of skidding and improves overall safety.

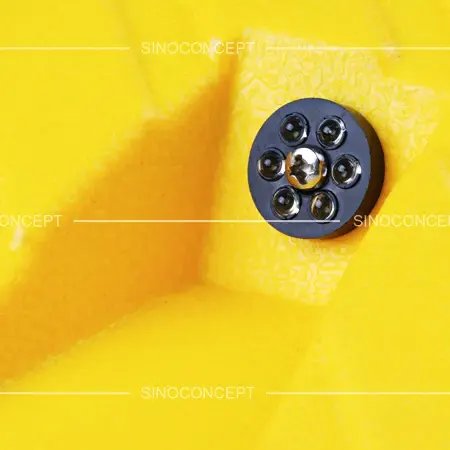

Highly Visible

All our speed ramps come with integrated glass bead reflectors for enhanced visibility in low-light conditions. This helps drivers spot our bumps from a distance, reducing the risk of traffic collisions.

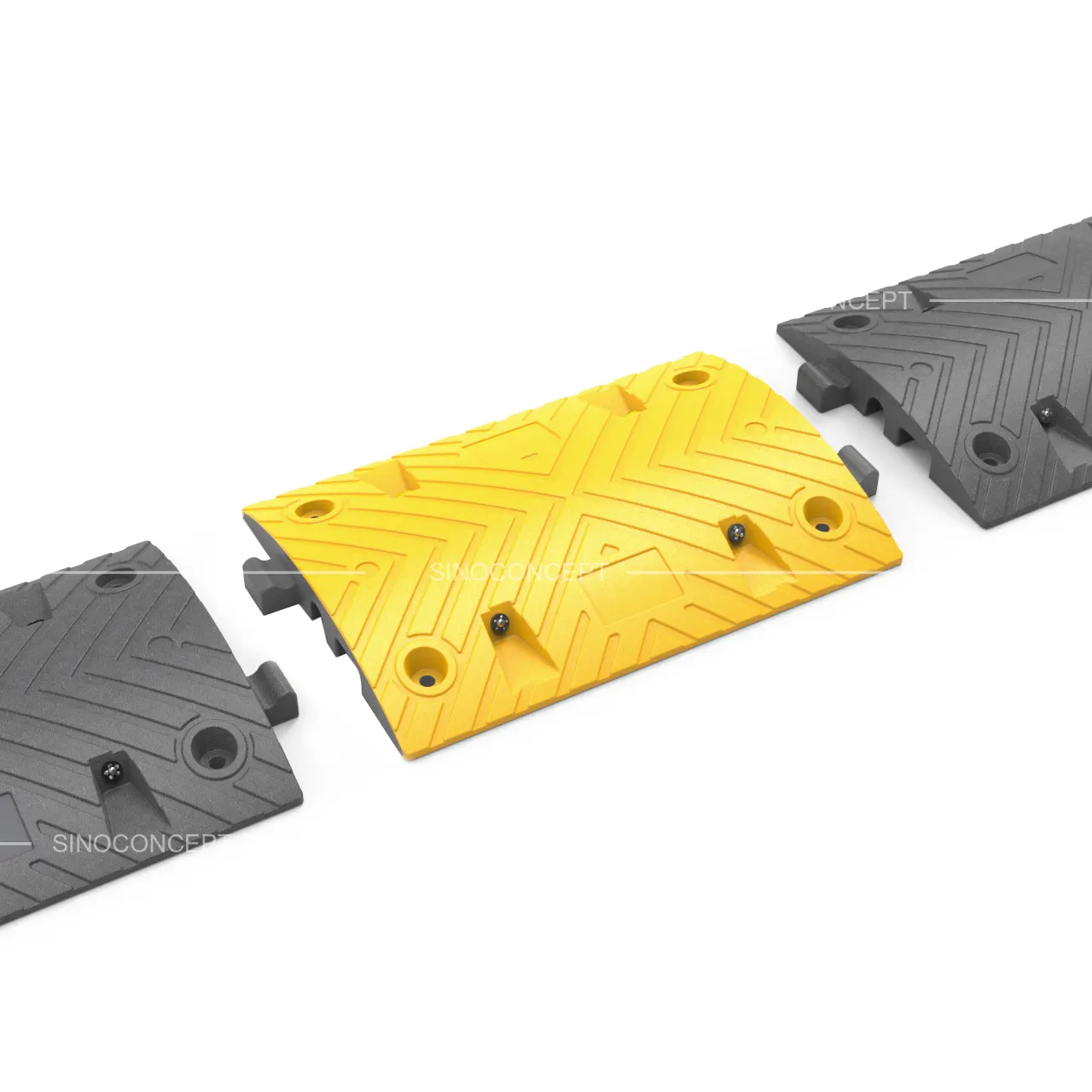

Interlocking System

Our speed bumps and road humps feature a built-in interlocking system with male and female connectors for easy length extension, ensuring they connect securely and stay in place during use.

Discover Our Wide Road Humps Range

We offer several types of speed bumps and humps in different dimensions, making it easy to find the right solution for requirement.

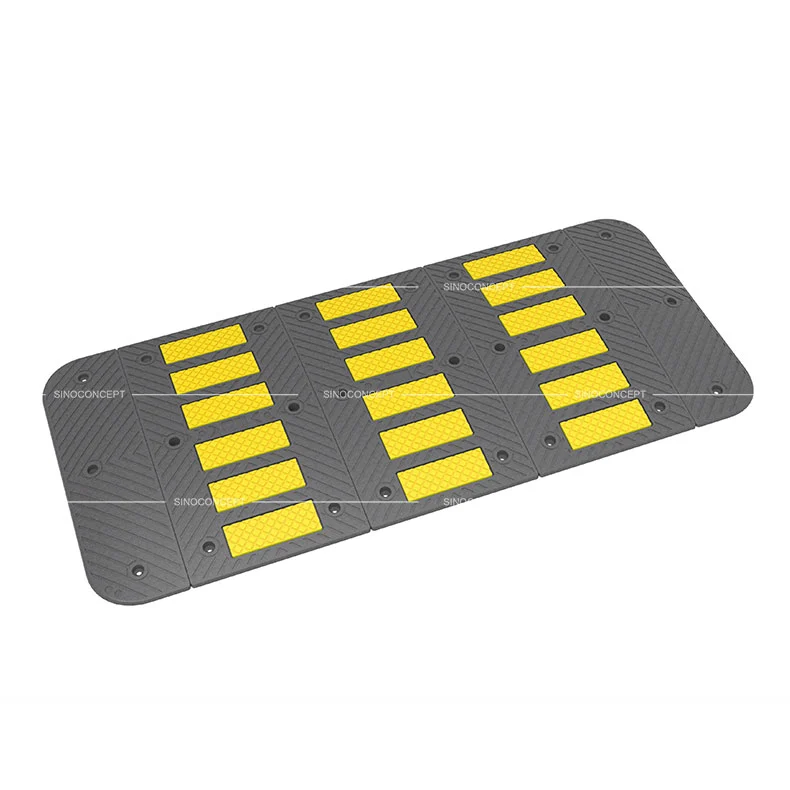

Speed Bumps 5 cm & 7 cm

Our road speed bumps can be freely extended and are suitable for private roads or retail car parks where speeding needs to be clearly discouraged.

- Available in standard (up to 20 tons/axle) and heavy-duty (up to 40 tons/axle) versions

- Built-in cable channel on heavy-duty models (Ø 30 mm or Ø 35 mm, depending on height)

- Glass bead reflectors for visibility in low-light conditions

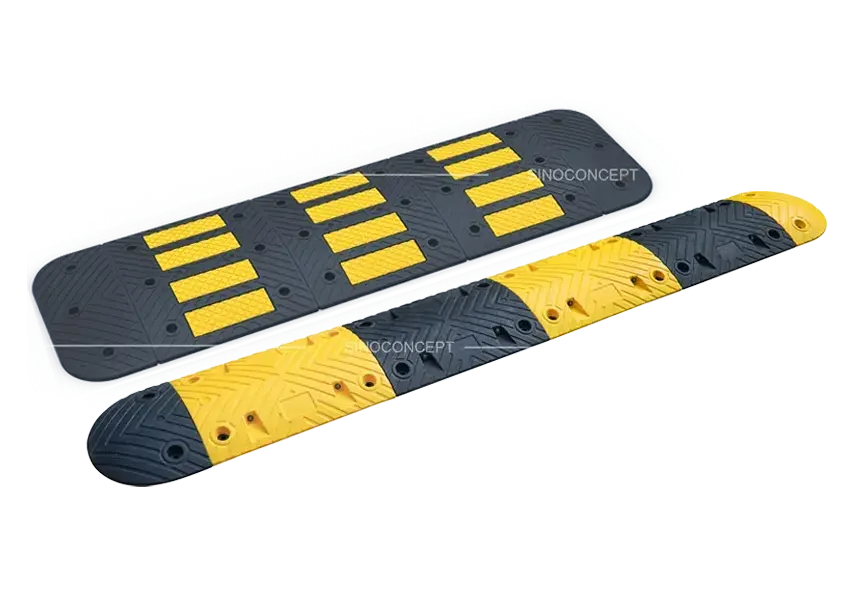

One-Part Speed Bump

Our one-part speed bump provides a cost-effective, quick-to-install solution for reliable traffic speed control to slow cars.

- 1830 mm single-piece middle section with 150 mm end caps

- Two Ø 30 mm built-in cable channels for cable protection

- Glass bead reflectors for visibility during the day and night

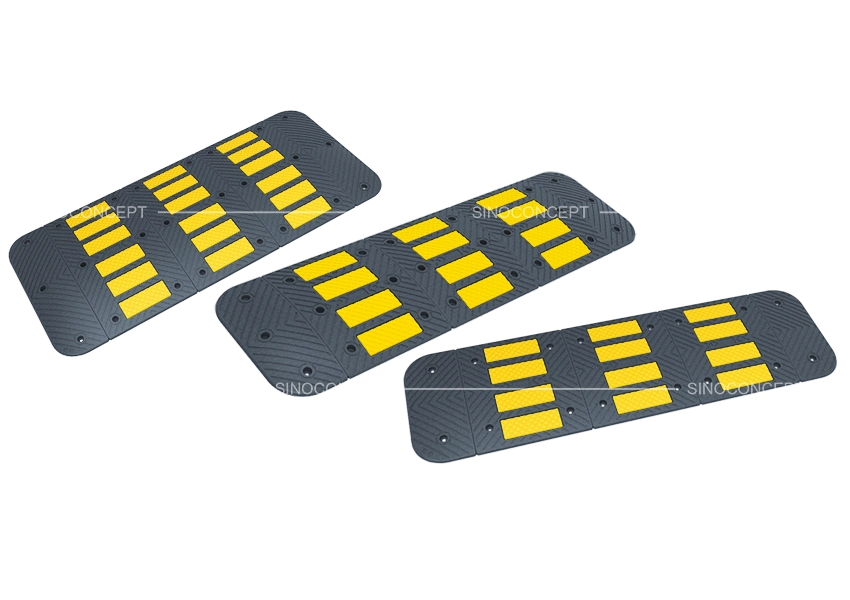

Road Humps 3 cm & 5 cm & 7 cm

Our traffic calming humps are wider and smoother than speed bumps. They help slow traffic smoothly, making them suitable for pedestrian crossing areas with low speed limits.

- Available in 3 cm, 5 cm and 7 cm heights to suit different vehicle types and speed targets

- Widths include 600 mm, 900 mm and 1200 mm, based on the type selected

- Two built-in cable channels on 5 cm and 7 cm models (Ø 30 mm or Ø 45 mm, depending on width)

Why Choose Sino Concept for Your Sleeping Policeman

At Sino Concept, we specialise in supplying reliable traffic calming solutions for professional use. With years of experience in the industry. We offer:

- Competitive factory-direct pricing with no middlemen

- REACH-compliant materials and in-house design

- Professional quality control team

- Easy and worry-free logistics

We Offer More Than Just Speed Ramps

In addition to speed bumps and road humps, we also offer a wide range of other traffic calming products to meet your specific needs.

| Picture | Range | Ideal For |

|---|---|---|

|

Wheel stops and parking blocks | Used in parking areas to guide vehicles into position and enhance safety |

|

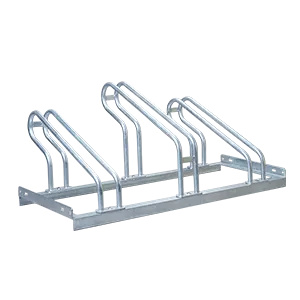

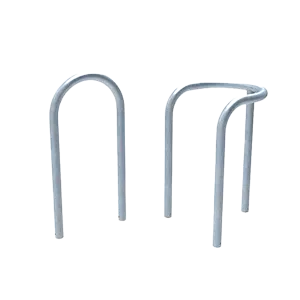

Cycle racks and cycle stands | Secure and efficient storage solutions for bicycles in parks, universities, etc |

|

Lockable Parking Barriers | Ideal for securing parking spaces and controlling vehicle access in both private and public areas |

|

Hoop Barriers & Lamp Post Protectors | Durable protectors to safeguard lamp posts and other infrastructure |

|

EV Charger Protection | Designed to protect electric vehicle charging stations from vehicle damage |

Contact Us Today for Heavy Duty Speed Bumps!

Sino Concept’s speed bumps meet relevant speed bump size regulations in Europe.

And our design makes installing speed bumps easy and built for long-term performance in cold weather.

Looking for a reliable car speed control supplier? Contact us today to request a quote or discuss your project. Our sales team is ready to assist!