EV charger protection

EV charger protection is reliable car park safety equipment used to protect electric vehicle charging stations from bumps and damage. They help create safer and organised areas around charging points. Our range includes wheel stops, hoop barriers and post protectors designed to improve safety and visibility in busy parking areas.

-

Wheel Stop 550 mm

$9.70 -

Wheel Stop 900 mm

$13.70 -

Wheel Stop 1220 mm

$18.20 -

Wheel Stop 1830 mm

$24.40 -

HGV Wheel Stops

$61.10

What Is EV Charger Protection?

As electric vehicles become more common, keeping charging stations safe and organised is important.

To avoid accidental damage, many areas use wheel stops, barriers and bollards to protect charging stations. We supply these products to support safer and well-organised EV charging points.

Why You Need EV Charger Protection Equipment?

EV charging points are an important part of modern transport. As more people use electric vehicles, these stations are now found in many places. But they can be at risk from cars bumping into them.

Using strong protection like hoop barriers or bollards helps prevent damage and keeps the charging points safe. It shows the area is well-managed and secure, helping both EV drivers and site owners feel safer.

Wheel Stops for Charging Point Protection

Sino Concept’s wheel stops are suitable for EV charging areas and Petrol station. They help stop cars from hitting equipment when reversing.

They are made from a strong Plastic-Rubber composite and work with all types of cars, including electric vehicles and hybrid vehicles.

We offer different sizes in our range:

Our wheel stops are easy to install and made to stay strong over time. Choose the right size for your site or ask our team for advice.

Hoop Barriers for Charging Station

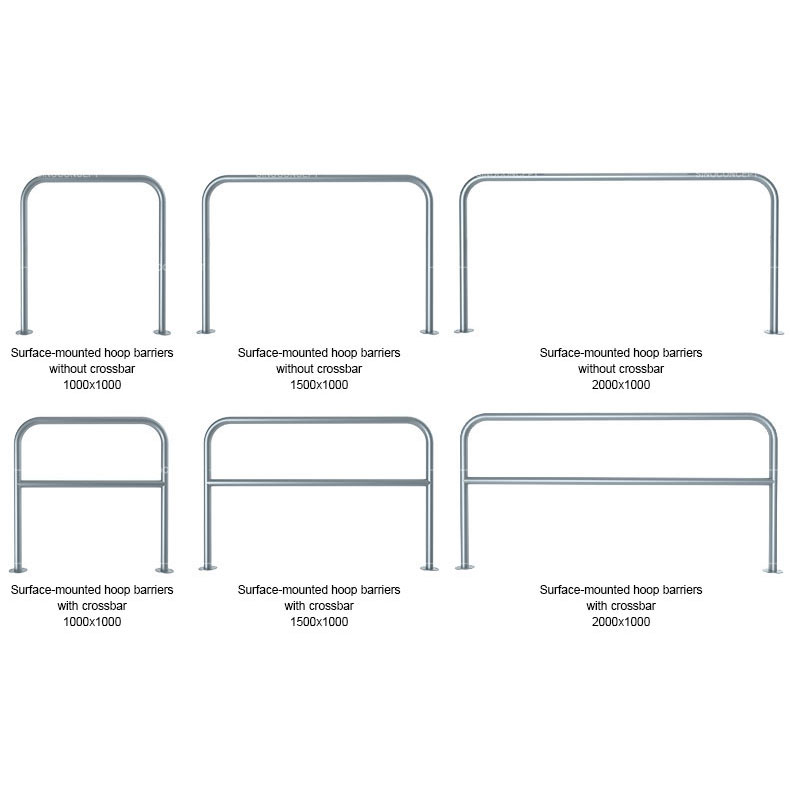

At Sino Concept, we offer strong galvanised hoop barriers to protect EV charging stations. They help stop cars from hitting the chargers and keep the area safe and tidy.

To suit different sites, we offer different types of Hoop Barriers: high or low, surface-mounted or embedded, with or without crossbars.

You can view the full range below:

- Hooped perimeter barrier (with or without crossbar)

- Hooped perimeter barrier low level

Need help choosing the right model? Our team is here to help. Just tell us your project needs and we’ll guide you to the best option.

Protective Bollards & Pole and Column Protector

At Sino Concept, we supply strong galvanised post protectors to help protect EV charging stations and nearby posts or columns. These bollards are designed to prevent impact from vehicles and maintain a safe, well-managed charging environment.

To match different layouts, we offer options such as round-arched and three-leg designs, with root-fixed or surface-mounted installation.

You can discover the full range here:

Our post protectors are strong and reliable for protecting electric vehicle charging. Choose the design that fits your site, or contact us for help!

Interested in Other Traffic Safety Products?

At Sino Concept, we also have a wide range of products to help improve car park and road safety.

These are often used in streets, warehouses, and other busy places. Here are some of our popular product types:

- Speed Bumps & Speed Humps: These help slow down vehicles and improve safety in areas like warehouse zones, private roads and car parks.

- Cycle Racks & Cycle Stands: These give people a safe and easy way to park their bikes in public or private areas.

- Lockable Parking Barriers: Used to block or reserve parking spaces and stop others from using them without permission.

Contact Us for More About Electric Vehicle Equipment!

Need the right protection for EV charging stations? We’re here to support your project and can check product availability for you.

We offer smart protection solutions that work with many types of charging stations and sites. Just tell us what you need, and we’ll help you choose the best option for your location.